High-purity quartz ore plays a vital role in semiconductor manufacturing and has long been regarded as the “raw material lifeline” of the chip industry. The production of high-purity silicon, a critical material for semiconductors, fundamentally depends on high-purity quartz. With the advancement of China’s semiconductor technology, quartz products have emerged as indispensable high-purity foundational materials, now classified as a strategic and pillar industry for national development.

As essential consumables in semiconductor processes, quartz products are utilized across the entire semiconductor supply chain. Key applications include diffusion, oxidation, deposition, photolithography, etching, and cleaning.

From a product perspective, semiconductor quartz components, quartz substrates, and quartz glass (including crucibles) represent the primary quartz-based products in the industry. Globally, these three categories account for market shares distributed approximately in a 4:3:3 ratio.

The unique properties of quartz

Quartz possesses exceptional physicochemical stability, featuring high temperature resistance, corrosion resistance, excellent light transmission, and superior insulation properties. These inherent characteristics give quartz unparalleled advantages in semiconductor manufacturing.

High-purity quartz sand, with its unique molecular chain structure, crystal lattice configuration, and distinctive lattice transformation patterns, demonstrates:

·Outstanding chemical stability

·Extremely low coefficient of volume expansion

·Remarkable thermal endurance

·High dielectric strength

These exceptional properties enable quartz-based components to maintain reliable and stable performance throughout semiconductor fabrication processes.

Application of Quartz in Semiconductor Manufacturing

In fact, the semiconductor industry has extremely high requirements for the purity of quartz. In the semiconductor production process, whether it is the production of single-crystal silicon by the Czochralski method, or the cleaning of single-crystal silicon and printed integrated circuits, high-purity quartz sand, silicon powder, polycrystalline silicon, quartz crucibles, quartz glass and other products are needed.

Single crystal silicon pulling

High-purity quartz crucible is a key component for pulling single crystal silicon. Its performance directly affects the crystallization rate and quality of single crystal silicon.

Wafer manufacturing

In the wafer manufacturing process, quartz glass diffusers, quartz flanges, quartz glass furnace tubes, quartz boats and other quartz glass equipment play an important role. They ensure the stability and purity of the wafers during the manufacturing process.

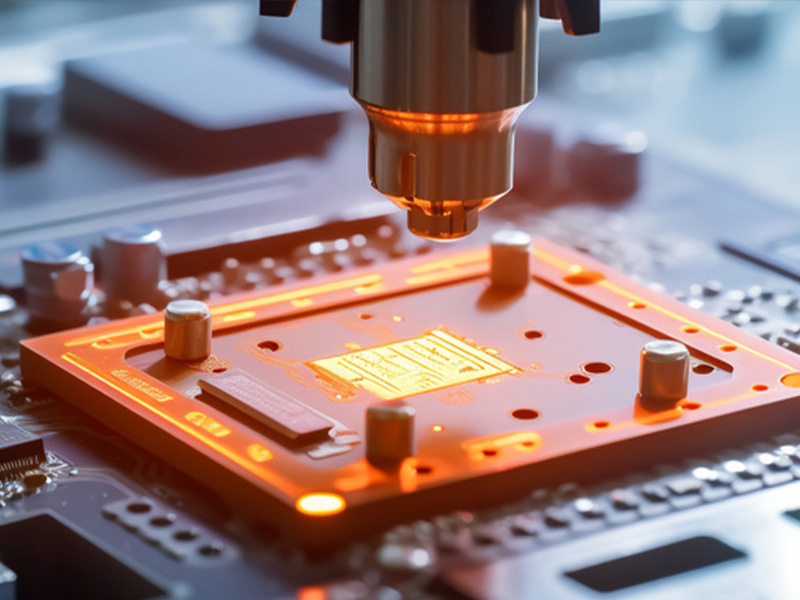

Chip Manufacturing

In the chip manufacturing process, quartz products such as photomask substrates used in processes such as lithography, etching and thin film deposition are crucial to the performance and yield of chips. In addition, as the size of wafers increases, the types and quantities of quartz glass products used in semiconductor production lines also increase accordingly, and quartz products have become hard consumables in semiconductor production lines.

What is the current market situation?

It goes without saying that quartz plays an important role in semiconductor manufacturing, but the domestic quartz products market still faces many challenges, such as monopoly of raw material supply and difficulty in equipment manufacturer certification. The domestic high-purity quartz sand market is highly monopolized, high-quality mineral sources are scarce, and the purification process is difficult. This restricts the development of the domestic quartz products industry. Quartz products are a highly customer-oriented industry, and they need to be certified by equipment manufacturers to enter the supply chain. This places extremely high demands on the process and management levels of quartz product manufacturers. At present, the proportion of high-end products of domestic quartz product manufacturers in the semiconductor manufacturing field is relatively low, mainly used in the photovoltaic field, resulting in an overall profit margin lower than that of overseas markets. However, with the expansion of the scale of global wafer fabs brought about by the semiconductor boom cycle, the corresponding quartz market is also expected to maintain the same proportion of growth, which also provides development opportunities for domestic quartz product manufacturers. Some leading companies such as Quartz Shares and CapitaLand Quartz have stepped up the certification of electronic-grade semiconductor quartz products and have made significant progress.