Quartz generally refers to low-temperature quartz (α quartz), and in a broad sense, quartz also includes high-temperature quartz (β quartz) and coesite, etc. It is one of the most common rock-forming minerals in nature. The main component of quartz is SiO2, which is colorless and transparent, but often shows different colors due to some inclusions and trace elements. It is generally white, colorless, smoky, glassy, and greasy on the fracture. The specific gravity is 2.22~2.65, the Mohs hardness is 7.0, the pH value is 6.0, the melting point is 1750℃, and it has piezoelectricity. Quartz is non-toxic, odorless, pollution-free, has good temperature resistance, acid and alkali corrosion resistance, poor thermal conductivity, high insulation, low expansion, stable chemical properties, and high hardness. It is widely used in glass, refractory materials, ceramics, casting, chemical industry, environmental protection, grinding, building materials and other industries. Among them, the glass manufacturing industry and building materials industry have a large demand for quartz resources, and the demand is growing at an annual rate of 8%. High-purity quartz extracted from high-quality quartz raw materials is widely used in high-tech industries such as semiconductors, aerospace, military, communications, photovoltaics, etc. and is listed as a strategic emerging material. At present, my country is self-sufficient in low-end quartz products, and mid-to-high-end products mainly rely on imports (Hao Wenjun, 2020; Yan Lingya, 2020).

Jiangxi Province spans two ancient plates, the Yangtze and Huaxia plates, with a long geological history, frequent magmatic activities, and distinctive metamorphism, forming quartz resources of various genetic types, with obvious resource advantages, especially the geological conditions for the formation of high-purity quartz mineral raw materials. This paper sorts out the current status and distribution characteristics of quartz resources in Jiangxi Province, analyzes the current application status of quartz resources, discusses the feasibility of using granite quartz and quartzite as high-purity quartz raw materials, and further proposes suggestions for the development and utilization of quartz resources in Jiangxi Province, in order to attract the attention of the provincial level and colleagues in the industry.

Resource status and distribution characteristics

Jiangxi is rich in quartz resources. According to industrial types, there are seven categories: natural crystal, quartzite, quartz sandstone, quartz sand, powder quartz, vein quartz and granite quartz (Table 1). According to the Jiangxi Provincial Mineral Resources Reserve Table (as of the end of 2019), there are 244 known quartz deposits in Jiangxi Province (Figure 1a), with proven resource reserves of 524,605.2 thousand tons (Figure 1b). In terms of the number of mineral deposits, vein quartz is the largest, accounting for more than half, followed by quartzite and quartz sandstone, accounting for 22% and 15% respectively, followed by powder quartz and quartz sand, accounting for less than 5%, and the least is natural crystal, accounting for only 1%; in terms of proven resource reserves, quartz sandstone, quartzite and quartz sand are the main ones, and the sum of the three accounts for 90% of the total proven resources. The others are vein quartz and powder quartz, accounting for 6% and 4% respectively. The proven resources of natural crystal are very small, accounting for about one ten-thousandth. Jiangxi’s proven quartz resources rank high in the country, among which pink quartz and vein quartz account for more than 25%, ranking first in the country.

1.1 Natural crystal

Natural crystals are mainly quartz vein type and pegmatite type. The crystal caves developed in quartz veins are generally located in the expanded parts or intersections of the vein body, and the crystal caves developed in pegmatites are generally located in the core. There are many vein quartz and pegmatites in Jiangxi, and they are widely distributed. Crystal mines have been discovered many times. More than 100 natural crystal mineral (chemical) points have been discovered, but most of them have not been developed and utilized to a high degree because they have not formed a large-scale development. Among them, the natural crystal mines in the above table are only Xiaomu Mountain in Lushan City and Dazu Mantou Mountain in Gao’an City. The resources in the mining areas are exhausted and mining has been stopped.

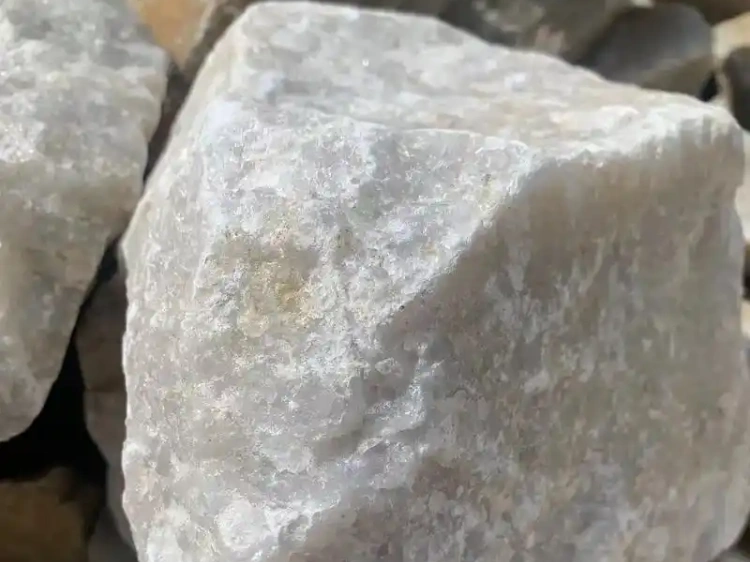

1.2 Quartzite

Quartzite is a metamorphic rock mainly composed of quartz, which is formed by recrystallization of quartz sandstone or other siliceous rocks through regional metamorphism. There are 53 quartzite deposits in Jiangxi, with a proven resource reserve of 157,263.56 thousand tons. Known quartzite mines are mainly distributed in the Jinggangshan-Suichuan area of the Luoxiao-Zhuguang uplift, and Wuning, Xiushui, Lushan, Jing’an, Fengxin, Tonggu, Yifeng, Wanzai, Gao’an and other areas of the Jiuling uplift; scattered distribution in Pingxiang-Anfu of the Wugongshan uplift, Shicheng-Guangchang of the Wuyi uplift, Dexing-Leping of the Wannian nappe uplift and other areas.

1.3 Quartz sandstone

Quartz sandstone is a consolidated marine and lacustrine sedimentary sandy rock with a quartz content of more than 90%. There are 37 quartz sandstone mines in Jiangxi, with a proven resource reserve of 173,740.3 kilotons. Known quartz sandstone mines are mainly distributed in Leping, Yushan, Guangfeng, Guixi, Yiyang, Yujiang and other areas in northeast Jiangxi, as well as Ji’an area; they are scattered in Ruichang, Tonggu in northern Jiangxi, and Ruijin, Xinfeng, Quannan and other areas in southern Jiangxi. Quartz sandstone in Jiangxi is mainly found in sedimentary cover since the late Paleozoic, mainly in Devonian-Jurassic strata. The ore-bearing strata include the Devonian Tiaomajian Formation, Lingyan Temple Formation, Yunshan Formation, Zhongpeng Formation, Zhangqiu Formation, Yanghu Formation, Guanshan Formation, Leigutai Formation, Carboniferous Outangdi Formation, Permian Leping Formation, Triassic Anyuan Formation and Jurassic Shuibei Formation and Zhangping Formation.

1.4 Quartz sand

Quartz sand is a sand-like quartz mineral raw material with quartz as the main mineral component, which is formed by natural weathering and transportation of granite, quartzite, quartz sandstone and vein quartz. There are 9 quartz sand mines in Jiangxi, with a proven resource reserve of 141,001.27 thousand tons. Known quartz sand mines are mainly distributed in the area around Poyang Lake, including Hukou, Duchang, Lushan, Yongxiu, etc. The large-scale ones are Songmen Island Quartz Sand Mining Area in Yongxiu County and Zheji Quartz Sand Mining Area in Hukou County; others are scattered in Ruijin, Shanggao and other areas. Quartz sand in Jiangxi mainly comes from lacustrine sedimentary quartz sand in modern lakes and alluvial sand along the river. It is divided into lake formation and river formation. Lake formation is most developed in large-scale lakes. Poyang Lake is the largest freshwater lake in China, with rich quartz sand resources; river formation is more developed in large rivers, such as the five major rivers of Ganjiang River, Fuhe River, Raohe River, Xinjiang River and Xiuhe River.

1.5 Pink Quartz

Pink quartz is a natural powdered quartz with extremely fine particles and high silicon dioxide content. There are 11 pink quartz mines in Jiangxi, with a proven resource reserve of 22,201.1 thousand tons. It is known that pink quartz mines are mainly distributed in Pingxiang, Yichun, Lianhua, Anfu and other areas in western Jiangxi; scattered in Wuyuan, Shangrao in northeastern Jiangxi and Xinfeng, Yudu and other areas in southern Jiangxi. Among them, the four mining areas of Hejiatang in Pingxiang City, Maitian in Yichun City, Caijialing in Anfu County and Luofengtou in Xinfeng County are medium-sized. The pink quartz mine in Jiangxi belongs to the weathering type of siliceous rock (microcrystalline quartzite) deposit (Fang Yesen, 2010), and the ore-bearing strata are mainly Carboniferous-Permian strata, especially concentrated in the siliceous rock formation of the Maokou Formation and Chetou Formation in the Middle Permian.

1.6 Vein Quartz

Vein quartz has coarse crystal particles and very pure chemical composition. The SiO2 content is generally above 98%. There are 131 vein quartz mines in Jiangxi, with a proven resource reserve of 30,398.88 kilotonnes. It is known that vein quartz mines are numerous and widely distributed, mainly small-scale, with few large-scale ones. There are only three medium-sized vein quartz mines: Dafengshan in Xingan County, Nankeng in Jinjiang Township, Xiajiang County, and Zhannao in Chongyi County. Vein quartz is generally related to magmatic hydrothermal action, mainly formed along fault filling, and is most developed in granite and metamorphic rock areas. According to the “China Mineral Geology: Jiangxi Volume”, the vein quartz mines in Xiushui, Lushan, Wanzai, Gao’an, Xinyu, Chongren, Lichuan, Yushan and other places have good quartz quality, and the ore is milky white to colorless, transparent to translucent, with an SiO2 content of more than 99% and a Fe2O3 content of less than 0.04%. Regional faults and secondary faults in uplifted areas often form large-scale vein quartz mines. The greatest prospecting prospects are in Mufu Mountain, Jiuling Mountain, Wugong Mountain, Wuyi Mountain, Yu Mountain and Nanling Mountain.

1.7 Granite Quartz

Granite is extremely developed in Jiangxi, with an exposed area of 35,000 km2, accounting for 23.1% of the province’s area. Compared with other types of quartz, granite quartz has significant scale advantages and broad prospects for development and utilization. However, due to its low content (generally 20-35%), the current development and utilization level of granite quartz is relatively low, and it is mainly used as tailings and associated minerals.

Current status of quartz application and selection of high-purity quartz raw materials

The industrial type of quartz deposits is closely related to the characteristics of industrial applications. Wang Ling summarized the characteristics of industrial applications based on the characteristics of quartz of different industrial types of deposits (Wang Ling, 2019). High-purity quartz is an irreplaceable basic material in the development of national strategic industries and pillar industries. It is an indispensable and irreplaceable important functional material for high-tech industries such as semiconductor chips, solar photovoltaics, optical fiber communications, aerospace, precision optics and special glass. It is a truly “neck-stuck” mineral resource. Because of its important strategic position, it is called the “giant panda” in silicon dioxide (Wang Jiuyi, 2022). High-purity quartz raw materials refer to quartz raw materials that can be extracted from high-purity quartz through purification processes. The research on high-purity quartz raw materials is the frontier direction of quartz research in my country at present (Chen Junyuan, 2020; Wang Jiuyi, 2021). Natural crystal was the original raw material for producing high-purity quartz, but due to its small reserves and high prices, it is difficult to meet the needs of large-scale industrial production. Wang Ling (2014) pointed out that vein quartz and granite quartz are ideal raw materials for replacing natural crystal to process high-purity quartz mid-range and high-end products, but not all vein quartz and granite quartz can process high-purity quartz. Only a very small number, or even very few, can process high-end products. Previous researchers (Tian Qingyue, 2017; Wang Ting, 2018; Wang Yunyue, 2020) have conducted a lot of research on vein quartz as a high-purity quartz raw material and achieved remarkable results, but the research on granite quartz and quartzite is relatively low. In recent years, the Jiangxi Institute of Geological Survey has carried out relevant research work and believes that granite quartz and quartzite formed under specific geological conditions are potentially favorable high-purity quartz raw materials.

2.1 Granite Quartz

Granite quartz is an ideal raw material for extracting high-purity quartz because of its slow crystallization and long time, and it is relatively pure. The world’s most famous IOTA series of high-purity quartz sand comes from the white granite in the Spruce Pine area of the United States. Domestic research results have confirmed that granite quartz formed under certain specific geological conditions can be used to extract high-purity quartz (Zhang Ye, 2012; Zhang Yanyan, 2018; Cong Jinyao, 2019; Zhao Jinzhou, 2022). After extensive investigation and comprehensive research, the author believes that pegmatite, pegmatite granite and muscovite pegmatite granite are potentially favorable high-purity quartz raw materials. Large-scale and high-quality high-purity quartz raw materials have been discovered, represented by Yihuang Tangyin and Ningdu Wangxi Village. Yihuang Tangyin pegmatite① is distributed in belts and intrudes into the medium-fine-grained biotite monzogranite. There are 5 large-scale pegmatites, which are large vein-like and cystic, with a long axis of NEE trend, 265-650 meters long, 6-80 meters wide, and an overall inclination of NNW, and a local inclination of SSE. The occurrence is relatively steep, generally 65-85°. Pegmatites are mainly composed of feldspar, quartz and muscovite, followed by tourmaline, with garnet as the characteristic mineral. The main impurity elements of high-quality quartz in Tangyin pegmatite are Al54.34×10-6, Li0.34×10-6, and Ti25.46×10-6, which have the potential to be purified to high-purity quartz of 99.992% or more; the impurity elements of general quartz are Al54-200×10-6, Li0.33-17×10-6, and Ti3-40×10-6, which have the potential to be purified to high-purity quartz of 99.98% or more. The white mica pegmatite granite in Wangxi Village, Ningdu②, is produced in the form of a rock tumor, with an irregular elliptical plane, a near east-west trend, a length of more than 300 meters, and a width of about 160 meters. It is found in medium-coarse-grained porphyritic biotite monzonite granite. The main minerals of white mica pegmatite are feldspar, quartz and white mica, and there are very few dark minerals. The main impurity elements of Wangxi Village muscovite pegmatite granite quartz are Al54.94×10-6, Ti13.71×10-6, and Li1.03×10-6, and it has the potential to be purified to high-purity quartz above 99.991%, and it is predicted to be large-scale or above.

2.2 Quartzite

Quartzite is formed by metamorphism of quartz sandstone or other siliceous rocks. Metamorphism causes the original impurity elements in quartz to migrate, thereby improving the purity of quartz. Mülleretal (2007) studied kyanite quartzite in northern Norway and found that the impurity element content in quartz is low, there are few fluid inclusions, and the grain boundaries between quartz and other minerals are mostly flat. Yang Xiaoyong (2021) believes that retrograde metamorphism affects the original trace element composition of quartz. During the retrograde metamorphism, quartz undergoes lattice recovery, accompanied by the shrinkage of the grain boundary area and the migration of grain boundaries, which is conducive to healing the lattice defects of quartz and expelling the impurity elements in the lattice (such as Al, Ti, etc.) to the grain boundary or concentrating them into inclusions. Quartzite in Jiangxi is mainly distributed in Precambrian metamorphic strata. Representative quartzite-bearing strata include the Nanhua Xiafang Formation, Shabahuang Formation, Hongshan Formation, Sinian Laohutang Formation and Cambrian Waiguankeng Formation, which are widely distributed in central and southern Jiangxi. The SiO2 content of quartzite is over 98%. Due to the superposition of magma contact thermal metamorphism or some positively correlated tectonic actions, the quartz can be further purified naturally. There are very few gas-liquid inclusions inside the quartz, and the SiO2 content is increased to over 99%. It is preliminarily judged that it has the potential to be high-quality and high-purity quartz raw material.

Development and utilization suggestions

(1) It is recommended to conduct research on the development and utilization of different types of quartz resources to understand the application status of Jiangxi’s quartz high-tech industry.

With the rapid development of social economy and science and technology, in addition to the steady growth in demand for quartz resources in traditional industries, the semiconductor, photovoltaic, and communications industries are extremely popular, and the demand for quartz resources has increased significantly. In addition, the shortage of high-quality quartz resources has resulted in insufficient overall production capacity and limited supply of quartz resources in my country. On the other hand, the high-tech field has higher and higher requirements for quartz purity. High-purity quartz has been listed as a strategic resource by some major countries and powers (Guo Jia, 2018; Chen Qishen, 2021), and the production technology of medium- and high-end high-purity quartz sand has been included in the high-tech field by governments of various countries and is strictly protected. Jiangxi is rich in quartz resources. In the past, there has been no systematic investigation and research on resources and their development status across the province. By conducting research on the development and utilization of different types of quartz resources, we can understand the status of resources and their development and utilization, analyze the supply and demand situation, especially the quality of quartz mineral raw materials, the extension of the industrial chain, and the application in high-tech industries, to provide technical support for the development of Jiangxi’s high-tech industries and related industrial development plans.

(2) It is recommended that high-purity quartz siliceous raw materials be included in the province’s key exploration minerals, and efforts should be made to increase prospecting and scientific research to provide resource guarantees for the rapid development of Jiangxi’s emerging industries.

High-purity quartz is a key basic raw material in the field of high-end technology. It has national strategic significance for ensuring chip security, optical fiber security, photovoltaic security, and high-end device security. On November 7, 2018, the National Bureau of Statistics issued the “Classification of Strategic Emerging Industries (2018)”, which for the first time elevated high-purity quartz to the level of national strategic resources. The “Outline of the 14th Five-Year Plan for National Economic and Social Development of Jiangxi Province and the Long-Term Goals for 2035” pointed out that it is necessary to deepen the strategy of industrial strengthening, focus on emerging industries such as aviation, electronic information, equipment manufacturing, traditional Chinese medicine, new energy, and new materials based on advantages, vigorously implement the “2+6+N” high-quality leapfrog development action of the industry, resolutely fight the battle of upgrading the industrial base and modernizing the industrial chain, and create a highland for the transformation and upgrading of traditional industries and the cultivation and development of emerging industries in the country. With the concentrated development of industries such as electronic information (printed circuit boards, optoelectronic displays, semiconductor lighting), new energy (photovoltaics), and new materials (semiconductor new materials) in Jiangxi, the demand for high-purity quartz is showing a continuous growth trend. If the source problem of resources cannot be solved, the degree of dependence on imports will continue to increase. In order to better cultivate new growth points for high-tech industries and promote high-quality economic development in Jiangxi, it is recommended to include siliceous raw materials for high-purity quartz in the province’s key exploration minerals, increase financial investment, guide social investment, encourage and support geological survey units and scientific research institutes to carry out key technology research and development such as resource survey and evaluation, mineral processing and purification, make up for the shortcomings of upstream and midstream industries, and create a full industrial chain for the utilization of high-purity quartz.

(3)It is recommended to establish a classification and grading evaluation method for quartz raw materials to promote the scientific and efficient use of high-quality quartz resources.

Quartz is not only a non-metallic mineral with large volume consumption, but also a mineral urgently needed for high-end technology. The development and utilization of Jiangxi quartz resources has the prominent problem of low-quality utilization of high-quality resources, resulting in the loss and waste of high-quality quartz resources. The main reason is that the evaluation of quartz raw materials and their application research is not in-depth enough. Therefore, it is very important to carry out a comprehensive evaluation of quartz raw materials. It is recommended to carry out application adaptability research on the main quartz raw materials in Jiangxi according to the application field, and establish a raw material classification and grading evaluation method to facilitate the hierarchical development and scientific utilization of resources. Protect high-quality resources and ensure the demand for high-purity quartz raw materials in the high-tech field.

(4) It is recommended to establish a quartz resource development and utilization base based on the location and resource advantages to promote industrial development.

Jiangxi is rich in quartz resources, which are relatively concentrated according to their genesis types. Some areas have abundant large-scale, high-quality high-purity quartz raw materials. It is recommended that local governments rely on their resource advantages to establish quartz resource development and utilization bases; further optimize resource allocation, formulate preferential policies, build modern high-standard quartz industrial parks, attract social capital to invest in factory construction, vigorously promote the aggregation and development of the quartz industry, and create a high-purity quartz industrial base.

Conclusion

The quartz resources in Jiangxi are of various types, widely distributed and with large reserves. Among them, powder quartz and vein quartz are advantageous minerals, and the resource reserves rank first in the country. The type of quartz determines the industrial application. Quartzite, quartz sandstone and vein quartz are important glass raw materials. Powder quartz and vein quartz are the main raw materials for silicon micropowder. Granite quartz and quartzite are favorable high-purity quartz raw materials. In view of the current status and existing problems of the development and utilization of quartz resources in Jiangxi, four suggestions are put forward: 1) It is recommended to conduct a survey on the development and utilization of different types of quartz resources to find out the application of quartz high-tech industries in Jiangxi; 2) It is recommended to include siliceous raw materials for high-purity quartz in the province’s key exploration minerals, increase the intensity of prospecting and scientific research, and provide resource guarantees for the rapid development of emerging industries in Jiangxi; 3) It is recommended to establish a classification and grading evaluation method for quartz raw materials to promote the scientific and efficient use of high-quality quartz resources; 4) It is recommended to establish a quartz resource development and utilization base based on location and resource advantages to promote industrial development.