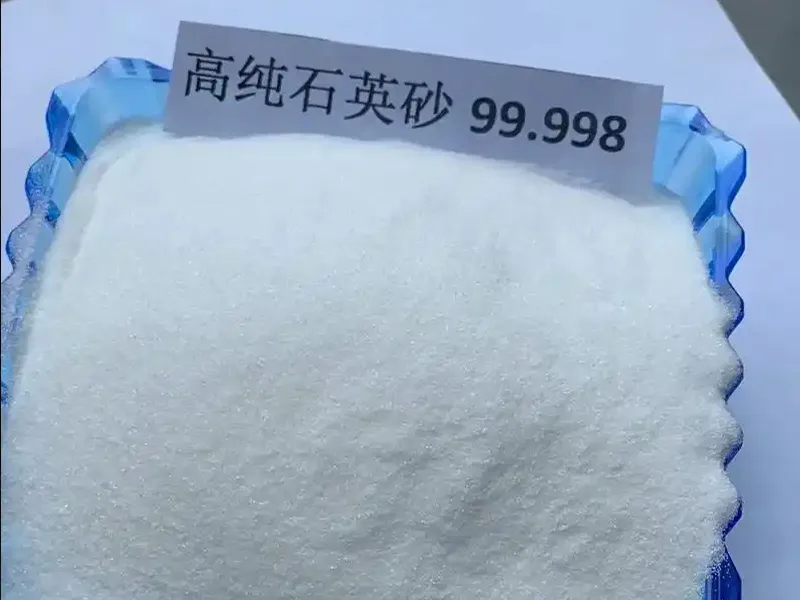

To turn quartz ore into high-purity quartz, we follow several steps. First, we process the minerals. Then, we use chemical purification. These steps help remove impurities. Our goal is to reach a silica (SiO2) content of over 99.95%. This process is key for creating quartz that meets advanced industry needs. It is used in semiconductors, fiber optics, solar panels, and electronics.

Key Steps in the Transformation Process

1. Mining and Initial Preparation

- Quartz ore comes from deposits that differ in their geological origin and impurity levels. The quality of raw quartz ore, such as granite pegmatites or metamorphic sources, affects its purification. This is because of the different mineral features and impurities present.

2. Crushing and Grinding

- The raw quartz ore is crushed using jaw crushers or gyratory crushers to reduce the size to manageable particles.

- Ball mills or rod mills grind the quartz further. This creates fine powder and increases the surface area for later chemical treatments.

3. Classification and Desliming

- The ground quartz is classified by particle size to ensure uniformity.

- Ultrasonic desliming may be used to remove fine clay and silt particles.

4. Magnetic and Electrostatic Separation

- Magnetic separation removes iron-bearing impurities and ferromagnetic minerals.

- Electrostatic separation targets non-magnetic impurities such as potassium, albite, aluminum, and micas.

5. Chemical Purification (Acid Leaching and Pickling)

- Acid leaching uses hydrochloric acid (HCl), sulfuric acid (H2SO4), hydrofluoric acid (HF), or their mixtures. It dissolves metals and impurities such as iron, aluminum, sodium, calcium, magnesium, and lead.

- This step is often conducted at controlled temperatures (60–80°C) with stirring to enhance impurity dissolution.

6. High-Temperature Treatments

- Calcination, which heats materials to about 850–1200°C, changes mineral structures. It removes volatile impurities and boosts quartz purity.

- Water quenching after calcination loosens mineral structures. This makes grinding and impurity removal easier.

7. Hot Chlorination Roasting

- In some processes, a hot chlorination step occurs at about 1200°C. This step uses chlorine and hydrogen chloride gas to remove leftover impurities. This step requires specialized facilities due to the hazardous gases involved.

8. Washing, Neutralization, and Drying

- After acid treatments, wash the quartz with deionized water. This step removes leftover acids and dissolved impurities.

- Neutralization steps ensure no acid remains that could contaminate the final product.

- The purified quartz is dried. It may also be calcined again to get the right physical and chemical properties.

Summary of the Process Flow

The transformation from quartz ore to high-purity quartz involves a series of mineral processing and chemical purification steps designed to remove impurities and achieve a very high silica (SiO2) content, typically above 99.95%. This process is critical for producing quartz suitable for advanced industrial applications such as semiconductors, fiber optics, solar panels, and electronics.

Key Steps in the Transformation Process

1. Mining and Initial Preparation

- Quartz ore is extracted from deposits, which vary in geological genesis and impurity content. The quality of the raw quartz ore (e.g., from granite pegmatite or metamorphic sources) affects the purification potential due to differences in mineralogical characteristics and impurity inclusions4.

2. Crushing and Grinding

- The raw quartz ore is crushed using jaw crushers or gyratory crushers to reduce the size to manageable particles.

- Further grinding is done in ball mills or rod mills to produce fine quartz powder, increasing surface area for subsequent chemical treatments23.

3. Classification and Desliming

- The ground quartz is classified by particle size to ensure uniformity.

- Ultrasonic desliming may be used to remove fine clay and silt particles1.

4. Magnetic and Electrostatic Separation

- Magnetic separation removes iron-bearing impurities and ferromagnetic minerals.

- Electrostatic separation targets non-magnetic impurities such as potassium, albite, aluminum, and micas35.

5. Chemical Purification (Acid Leaching and Pickling)

- Acid leaching with hydrochloric acid (HCl), sulfuric acid (H2SO4), hydrofluoric acid (HF), or mixtures thereof dissolves metallic and other impurities like iron, aluminum, sodium, calcium, magnesium, and lead.

- This step is often conducted at controlled temperatures (60–80°C) with stirring to enhance impurity dissolution256.

6. High-Temperature Treatments

- Calcination (heating at around 850–1200°C) is used to alter mineral structures, remove volatile impurities, and improve quartz purity.

- Water quenching after calcination helps loosen mineral structures for easier grinding and impurity removal15.

7. Hot Chlorination Roasting

- In some processes, a hot chlorination step at about 1200°C in a chlorine and hydrogen chloride gas atmosphere is applied to remove residual impurities chemically. This step requires specialized facilities due to the hazardous gases involved3.

8. Washing, Neutralization, and Drying

- After acid treatments, quartz is thoroughly washed with deionized water to remove residual acids and dissolved impurities.

- Neutralization steps ensure no acid remains that could contaminate the final product.

- The purified quartz is then dried and sometimes calcined again to achieve the desired physical and chemical properties256.

Summary of the Process Flow

| Stage | Purpose | Typical Methods/Conditions |

|---|---|---|

| Mining and Extraction | Obtain raw quartz ore | Open-pit or underground mining |

| Crushing and Grinding | Size reduction and surface area increase | Jaw crusher, ball mill, rod mill |

| Classification & Desliming | Remove fines and classify particle size | Ultrasonic desliming, classifiers |

| Magnetic & Electrostatic Separation | Remove magnetic and non-magnetic impurities | Magnetic separators, electrostatic separators |

| Acid Leaching / Pickling | Dissolve metallic and other impurities | HCl, HF, H2SO4 acids at 60–80°C |

| Calcination & Water Quenching | Structural alteration and impurity removal | Heating at 850–1200°C, rapid cooling |

| Hot Chlorination Roasting | Chemical impurity removal | Chlorine-HCl gas atmosphere at ~1200°C |

| Washing, Neutralization, Drying | Final impurity removal and drying | Deionized water washing, drying at ~175–185°C |

Purity Achieved and Challenges

- The final high-purity quartz product usually has SiO2 content of 99.95% or more. Sometimes, it can reach 99.97% or higher. This depends on the quality of the ore and how efficient the process is.

- Key impurities to remove are:

- Aluminum

- Iron

- Sodium

- Potassium

- Lithium

- Titanium

- Zirconium

- Calcium

- Magnesium

- The process needs special equipment and skilled operators. This matters for grinding tough quartz and handling hazardous chemicals in chlorination.

- The quartz ore’s geological origin and mineralization affect how easy and costly it is to purify.

To sum up, turning quartz ore into high-purity quartz is a complicated process. It includes several steps:

- Mechanical size reduction

- Physical separation

- Chemical leaching

- Thermal treatments

- Careful washing

These steps get rid of impurities. They also achieve the high silica purity that advanced technology industries need.