Quartz Dry Grinding Production Line

The quartz crushing process is the process of processing natural quartz ore into quartz powder of different particle sizes, which is widely used in glass, ceramics, electronics, construction and other industries.

The quartz ore extracted from the mine undergoes preliminary screening to remove impurities and ensure the purity of the raw materials.Use jaw crusher or hammer crusher to carry out preliminary crushing of quartz ore to break large pieces of quartz ore into smaller particles for subsequent processing.The quartz particles are further crushed to smaller particle sizes by cone crushers or impact crushers.Use ball mill, Raymond mill or air flow mill to deeply crush the quartz particles to achieve the required fineness.The crushed quartz powder is graded by a classifier or vibrating screen to ensure uniform particle size to meet customer needs.Use a magnetic separator or other iron removal equipment to remove iron impurities from quartz powder to improve product purity.

Equipment required for quartz crushing process

The quartz crushing process requires a variety of equipment to complete different stages of processing. The following is a list of commonly used equipment:

- Crushing Equipment

– Jaw crusher: used in the coarse crushing stage to process large pieces of quartz ore.

– Cone crusher: used in the medium crushing stage, with high efficiency and uniform particle size.

– Hammer crusher: suitable for crushing small and medium-sized quartz ores.

- Grinding Mill

-Ball mill: suitable for large-scale production, good crushing effect, suitable for fine powder processing.

-Raymond mill: suitable for small and medium-sized production, simple operation, low energy consumption.

-Jet mill: suitable for ultrafine powder processing, uniform particle size, suitable for high-purity quartz powder production.

- Classifyinging Equipment

– Classifier: used to classify powder to ensure consistent product size.

– Vibrating screen: used to screen quartz powder of different sizes.

- Iron Removal Equipment

– Magnetic separator: removes iron impurities from quartz powder and improves product purity.

The difference between choosing different devices

Depending on production needs and product requirements, choosing different equipment will have the following effects on the quartz crushing process:

- Particle size requirements

– If you need quartz powder of ordinary fineness, you can choose Raymond mill or ball mill.

– If you need ultrafine powder (such as above 400 mesh), it is recommended to choose air flow mill or ultrafine ball mill. - Production scale

– For small production lines, you can choose Raymond mill, which has low investment cost.

– For large production lines, it is recommended to choose ball mill or air flow mill, which is suitable for mass production. - Product purity

– For the production of high-purity quartz powder, air flow mill and magnetic separator are indispensable equipment.

– If the purity requirement is not high, you can choose ordinary crushing equipment. - Energy consumption and efficiency

– Raymond mill has low energy consumption and is suitable for small and medium-sized enterprises.

– Although the air flow mill has high energy consumption, it has high efficiency and is suitable for high-end product production. - Investment cost

– Enterprises with limited initial budget can choose Raymond mill and jaw crusher, which are cost-effective.

– If you pursue high quality and high efficiency, you can choose high-end equipment such as air flow mill and ultrafine ball mill.

Projects

Projects in these field

Quartz powder surface modification technology

The hydrophilic surface characteristics of quartz powder create compatibility challenges with organic polymer matrices.

Demystifying Quartz: The Seven Primary Source Types

Quartz, one of the most abundant minerals in Earth’s crust, is composed of silicon dioxide (SiO₂). Renowned for its exceptional properties—including high hardness,

What kind of ore can produce high-purity quartz?

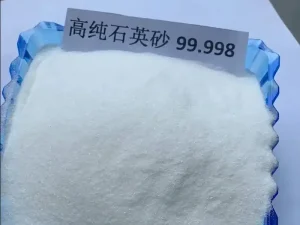

High-purity quartz (HPQ) is silica (SiO₂) with a purity of 99.95% or more.