High-Purity Quartz: Types, Origins, Impurities, and Processing Needs

- Types of Ore: Certain ores make high-purity quartz.

- Geological Origins: They come from specific geological settings.

- Impurity Profiles: Each type has a different impurity profile.

- Processing Requirements: Their processing needs vary for purity.

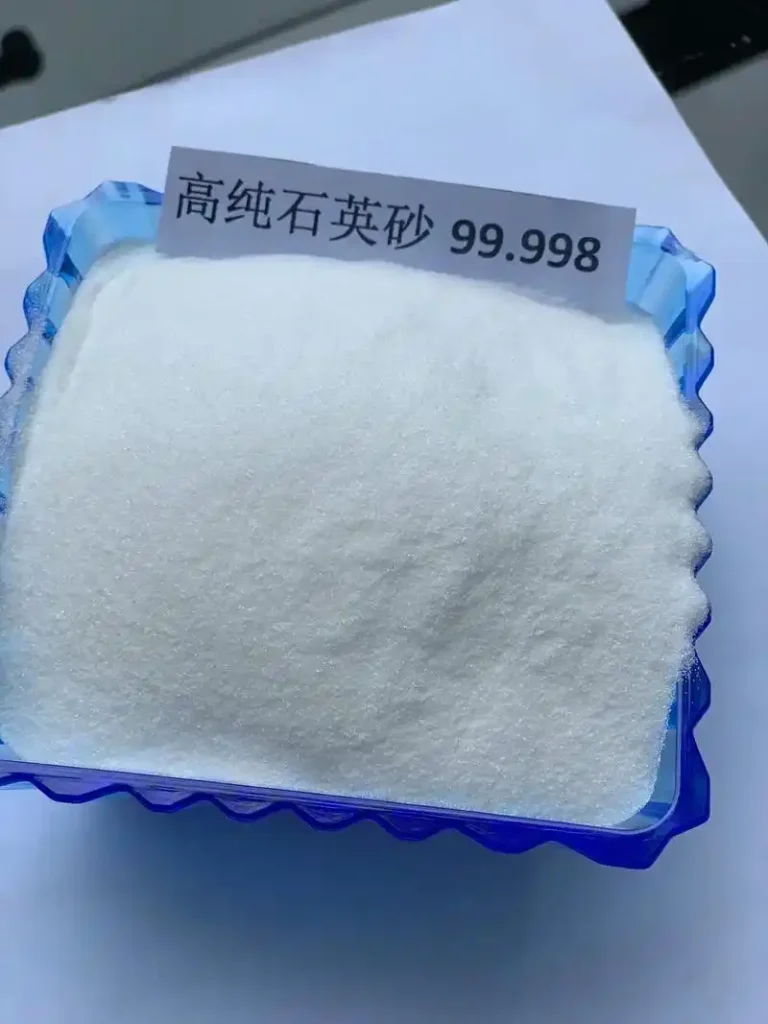

High-purity quartz (HPQ) is silica (SiO₂) with a purity of 99.95% or more. It is essential for advanced technologies like semiconductors, photovoltaic cells, and fiber optics. HPQ production depends on quartz ore sources, impurity levels, and methods to achieve the right purity. This report highlights the main ore types for HPQ production. It explores where they are found around the world. It also reviews the technical challenges each type brings.

Geological Classification of High-Purity Quartz Ores

1. Granite Pegmatite-Type Quartz

Granite pegmatites are coarse igneous rocks. They form during the last stages of magma crystallization. These deposits contain quartz as a primary mineral, often intergrown with feldspar and mica. The quartz content in pegmatites is low, usually around 25%. Its structure contains many fluid inclusions and trace impurities, such as Al, Li, and K. These make purification hard. Some pegmatites, such as those in the Altay region of Xinjiang, China, have yielded pilot products. These products have SiO₂ purity levels hitting 4N8 (99.998%). This was achieved using advanced acid leaching and thermal treatments.

Key Characteristics:

Impurity Profile: High levels of aluminum (Al³⁺) come from its place in the quartz lattice. Alkali metals, like sodium (Na⁺) and potassium (K⁺), are present from nearby feldspars.

Processing Requirements:

- Multi-stage grinding releases quartz from gangue minerals.

- Then, use HF-based leaching to dissolve inclusions.

2. Vein Quartz

Vein quartz develops from hydrothermal activity. Silica-rich fluids seep into fractures and fissures, causing precipitation. These deposits exhibit massive, milky-white quartz with SiO₂ content often exceeding 99%. Quartz veins in the Supe area of Cameroon have high-purity zones. For instance, sample QTZ6 shows Al levels below 15 ppm and Ti levels below 10 ppm. This occurs even with rutile and tourmaline inclusions present.

Key Characteristics:

Impurity Profile: Dominated by mineral inclusions (e.g., rutile, tourmaline) and fluid-trapped trace elements (e.g., Ti, Fe).

Processing Requirements:

- First, use optical sorting to remove inclusion-rich zones.

- Then, apply magnetic separation.

- Finally, use hot chlorination to get rid of Ti-bearing impurities.

3. Quartzite

Quartzite is a metamorphic rock derived from the recrystallization of quartz sandstone. High-grade quartzites, like those from Sibelco in Norway, have SiO₂ levels of 98% or more. They are key feedstocks for IOTA-standard HPQ. The mineral’s low porosity and homogeneous structure reduce fluid inclusions, simplifying purification.

Key Characteristics:

Impurity Profile: Trace amounts of Al and Ti from detrital minerals in the protolith.

Processing Requirements:

- Calcination at 1,200°C to break apart inclusion membranes.

- Use electrostatic separation to get rid of leftover heavy minerals.

4. Natural Crystal

Natural crystals, though rare, represent the purest form of quartz, with SiO₂ content often exceeding 99.99%. These crystals grow in geodes or hydrothermal veins. They form under slow-cooling conditions. This helps reduce lattice defects. However, their small deposit sizes and high mining costs limit industrial scalability.

Global Distribution of High-Purity Quartz Deposits

| Ore Type | Key Regions | Notable Deposits | SiO₂ Purity (Post-Processing) |

|---|---|---|---|

| Granite Pegmatite | Eastern Qinling (China), Altay (China) | Henan Pegmatite Field | 99.995% (4N5) |

| Vein Quartz | Cameroon, Brazil, U.S. (Spruce Pine) | Supe Hydrothermal Veins (Cameroon) | 99.97% (4N7) |

| Quartzite | Norway, Russia, Australia | Sibelco’s Norwegian Quartzite | 99.998% (4N8) |

| Natural Crystal | Madagascar, Brazil, Arkansas (U.S.) | Minas Gerais (Brazil) | 99.999% (5N) |

Impurity Removal Challenges by Ore Type

Aluminum (Al) Contamination

Primary Source: Substitutional Al³⁺ in the quartz lattice, particularly in granite pegmatites.

Removal Method: High-temperature chlorination (1,200°C) with Cl₂ gas to volatilize Al as AlCl₃.

Titanium (Ti) Contamination

Primary Source: Rutile (TiO₂) inclusions in vein quartz and quartzite.

Removal Method: Triboelectric separation or flotation to isolate Ti-rich particles.

Alkali Metals (Na, K, Li)

Primary Source: Fluid inclusions in pegmatitic quartz.

Removal Method: Crackling via thermal shock (water quenching) followed by HF leaching.

Economic and Technological Considerations

Resource Accessibility: Vein quartz and quartzite deposits are more economically viable than rare natural crystals.

Energy Intensity: Calcination and chlorination steps account for ~40% of processing costs, favoring regions with low energy tariffs.

Environmental Regulations: HF usage in leaching requires stringent waste management systems, limiting production in regions with strict environmental policies.

You can produce high-purity quartz from four main ore types:

- Granite pegmatites

- Vein quartz

- Quartzite

- Natural crystals

Each ore type presents distinct geological formations, impurity profiles, and processing pathways. New methods for removing impurities, especially Al and Ti, allow us to use deposits that were once too costly, like the hydrothermal veins in Cameroon. Established players like Sibelco show how key proprietary purification technologies are for staying at the top of the market. Future exploration must find quartzite and vein quartz deposits in less studied areas. Also, we should invest in cheap impurity removal methods. This will help diversify the global HPQ supply chain.